Forgings & Flanges

Flanges are used to provide support to pipework, for blocking off a pipeline or for connecting different items of a pipeline together.

Pipe flanges are usually discs/rings or collars that are welded or screwed to the pipe end and fastened with nuts and bolts. A gasket is inserted between the two mating flanges to provide a tighter seal.

Standard dimensions/pressure specifications have been developed, although there is still a need, depending upon the application, to consider bespoke flange manufacture. Alloy Flanges & Fittings supply standard or bespoke pipe flanges, from forgings or plate as required, and welcome enquiries to provide advice on the most suitable type or size of flange to be used in a particular configuration.

Below please find a short discussion of the differences and the advantages/disadvantages of the major types of flanges

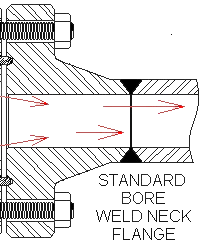

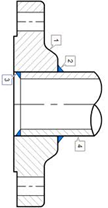

Weld Neck

The inside diameter of the weld neck pipe flange is machined to match the inside diameter of the pipe, which fits over the neck of the flange. The two elements are then connected by welding around the over-lapping seal area.

This configuration makes for a stronger connection (mechanical stresses are transferred from the weld neck pipe flange to the pipe itself) and there is a natural reduction in the high stress concentration at the base of the hub of the weld neck flange. This allows weld neck flanges to be used for much higher pressure applications than other flanges.

Amongst the grades of steel we can supply weld neck flanges in are stainless (such as 304, 316 and 321), duplex / super duplex (e.g. F44, F51, F53, F55), nickel alloys (including alloy 625, alloy 718), Titanium (grade 2 and 5), high yield carbon steel and 6 Moly steel.

Alloy Flanges & Fittings can supply against the major standards

- ASME/ASTM B16.5 – 0.5" - 24" in 150 lb – 2500 lb ratings

- ASME B1647 – up to 60" in 150 lb – 300 lb ratings

- ASME B647 - Series A (MSS SP44) - up to 47" in 600 lb – 900 lb ratings

- ASME B647 - Series B (API 605) - up to 60" in 75 lb – 300 lb ratings

- BS 3293 - up to 60" in 15 lb – 300 lb ratings or up to 48" in 600 lb – 900 lb ratings

- BS 10/AW/WA - up to 60" in Classes B, D, E, F, G, & H

- BS 4504/BS EN1092 - up to 60" in PN 2.5 – 250

- API 6a/6BX – UP TO 24" IN 3 – 20,000 psi rating

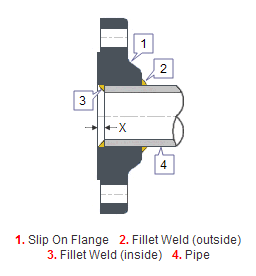

Slip-On

Slip-on flanges are machined with an inside diameter of the pipe flange slightly larger than the outside diameter of the pipe to be connected. This allows the flange to (slip-on) slide over the pipe with a tolerance to allow the connection to achieve a tight fit before welding completes the seal. Slip-on pipe flanges are secured to the pipe with a fillet weld at the top and bottom of the pipe connection.

Slip-on flanges are often chosen over other types of Weld Neck Flanges because of their lower cost, not only intrinsically but also in reduced fabrication costs (less accuracy required in cutting pipe to length, it is easier to align bolt holes and the squaring of flange faces, which all reduces installation costs).

Slip-on flanges can also be further categorised into ring or hub slip-ons. Both still slip-on the pipe, but those with a hub have standard published specifications that range from 1/2" through 96", while ring slip-on flanges have published standard specifications that range from 1/2" through 144".

Alloy Flanges & Fittings can supply slip-on flanges in stainless (such as 304, 316 and 321), duplex / super duplex (e.g. F44, F51, F53, F55), nickel alloys (including alloy 625, alloy 718), Titanium (grade 2 and 5), high yield carbon steel and 6 Moly steel.

We can supply against the major standards

- ASME/ASTM B16.5 – 0.5” - 24” in 150 lb – 2500 lb ratings

- BS 3293 - up to 60” in 15 lb – 300 lb ratings or up to 48” in 600 lb – 900 lb ratings

- BS 4504 / BS EN1092 - up to 60” in PN2.5 – 250

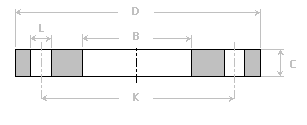

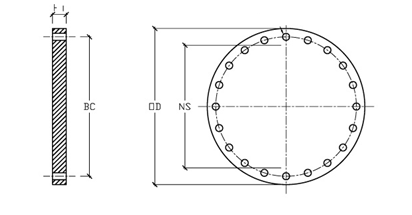

Blinds

Blind flanges are used to seal the end of a piping system or pressure vessel opening to prevent flow and content loss, while still allowing access for maintenance/inspection or for pressure testing the flow of liquid or gas through a pipe or vessel.

Blind pipe flanges can be used in most pressure applications

We can supply blind flanges in stainless (such as 304, 316 and 321), duplex/super duplex (e.g. F44, F51, F53, F55), nickel alloys (including alloy 625, alloy 718), Titanium (grade 2 and 5), high yield carbon steel and 6 Moly steel.

Alloy Flanges & Fittings can supply against the major standards

- ASME/ASTM B16.5 – 0.5” - 24” in 150 lb – 2500 lb ratings

- ASME B1647 – up to 60” in 150 lb – 300 lb ratings

- ASME B647 - Series A (MSS SP44) - up to 47” in 600 lb – 900 lb ratings

- ASME B647 - Series B (API 605) - up to 60” in 75 lb – 300 lb ratings

- BS 3293 - up to 60” in 15 lb – 300 lb ratings or up to 48” in 600 lb – 900 lb ratings

- BS 10/AW/WA - up to 60” in Classes B,D,E,F,G & H

- BS 4504/BS EN1092 - up to 60” in PN 2.5 – 250

- API 6a/6BX – UP TO 24” IN 3 – 20,000 psi rating

- API 590/ASME B16.48 – up to 24” in 150 lb – 2500 lb

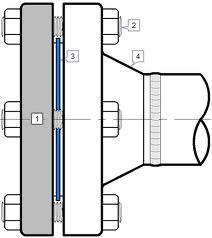

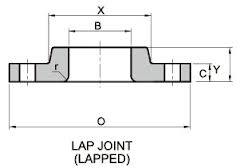

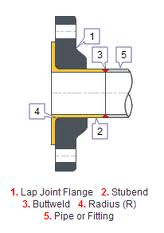

Lap Joint

|

|

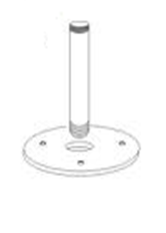

Lap joint flanges slide over the pipe and are most commonly used with Stub End Fittings.

Typically the pipe is welded to the Stub End and the lap joint flange is free to rotate around the stub end, eliminating issues with bolt hole alignment.

Lap joint flanges are often used in applications subject to frequent dismantling.

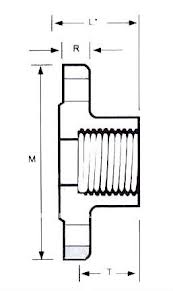

Threaded Pipe flanges

Threaded pipe flanges are similar to slip-on flanges except that the bore has tapered threads to accept pipes with matching external threads. This eliminates the need for welding to secure a strong seal. Threaded pipe flanges are best used for small diameter but high pressure environments.

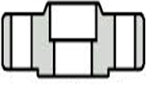

Socket Weld flanges

The pipe and flange are connected by inserting the pipe into the socket end of the flange, and then applying a fillet weld around the top of the seal.

This seal eliminates any possibility of weld material obstructing or constricting the bore and flow of the fluid or gas inside of the pipe. Socket-weld flanges are typically used to connect smaller sizes of high pressure pipes.

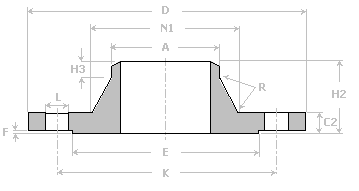

Flange Dimensions

The correct flange to use for a particular application is determined by the combination of the size of pipe to be connected and the pressure (class rating) the assembly will need to cater for.

Most of these dimensions have been standardized and published as ASME, MSS, API or other specifications, so that flanges can be used with reliability. However, there are still occasions when particular applications require bespoke flanges outside of those standards – Alloy Flanges & Fittings can provide both standard and non-standard flanges as required.

The most common dimension standard we are asked to supply to is ASME/ANSI B16.5, which provides dimensions and tolerances for flanges in pipe sizes from 1/2" through 24" and in classes ranging 150 lb through 2500 lb.

Please find attached the dimension values reproduced (by pipe size within class ratings).

ASTM B160 (STANDARD SPECIFICATION FOR NICKEL ROD AND BAR)

| ASTM B160 UNS N02200 | ASTM B160 UNS N02201 | ASTM B160 UNS N02211 |

ASTM B564 (STANDARD SPECIFICATION FOR NICKEL ALLOY FORGINGS)

ASTM B564 Nickel Copper Alloy UNS N04400

ASTM B564 Nickel Chromium Iron Alloy UNS N06600

ASTM B564 Nickel Chromium Iron Alloy UNS N06690

ASTM B564 Nickel – Iron Chromium Alloy UNS N08120

ASTM B564 Nickel Iron – Chromium Alloy UNS N08800

ASTM B564 Nickel Iron Chromium Alloy UNS N08810

ASTM B564 Nickel Chromium – Iron Aluminum Alloy UNS N06603

ASTM B564 Nickel Chromium – Iron Aluminum Alloy UNS N06025

ASTM B564 Nickel Chromium Iron- Silicon Alloy UNS N06045

ASTM B564 Low Carbon Nickel Molybdenum Chromium Tantalum Alloy UNS N06210

ASTM B564 Nickel- Iron Chromium Alloy UNS N08811

ASTM B564 Nickel- Chromium Molybdenum Columbium Alloy UNS N06625

ASTM B564 Nickel Chromium Molybdenum Tungsten Alloy UNS N06110

ASTM B564 Nickel-Iron Chromium Molybdenum Copper Alloy UNS N08825

ASTM B564 Low Carbon Nickel Molybdenum Chromium Alloy UNS N10276

ASTM B564 Low Carbon Nickel Molybdenum Chromium Alloy UNS N06022

ASTM B564 Iron-Nickel Chromium Molybdenum Nitrogen Alloy UNS N08367

ASTM B564 Low Carbon Nickel Chromium Molybdenum Alloy UNS N06059

ASTM B564 Low Carbon Nickel Chromium Molybdenum Alloy UNS N06058

ASTM B564 Low Carbon Nickel Chromium Molybdenum Alloy UNS N06035

ASTM B564 Low Carbon Nickel Chromium Molybdenum Alloy UNS N06200

ASTM B564 Nickel Chromium Molybdenum Silicon Alloy UNS N06219

ASTM B564 Low Carbon Nickel Iron Chromium Molybdenum Copper Alloy UNS N08031

ASTM B564 Nickel Chromium Tungsten Molybdenum Alloy UNS N06230

ASTM B564 Nickel Chromium Cobalt Molybdenum Alloy UNS N06617

ASTM B564 Nickel Molybdenum Alloy UNS N10629

ASTM B564 Nickel Molybdenum Alloy UNS N10665

ASTM B564 Nickel Molybdenum Alloy UNS N10675

ASTM B564 Nickel Molybdenum Chromium Iron Alloy UNS N10242

ASTM B564 Low Carbon Nickel Chromium Molybdenum Tungsten Alloy UNS N06686

ASTM B564 Nickel Cobalt Chromium Silicon Alloy UNS N12160

ASTM B564 Nickel Alloy UNS N02200

ASTM B564 Nickel Molybdenum Chromium Iron Alloy UNS N10624

ASTM B564 Chromium Nickel Iron Nitrogen Alloy UNS R20033

ASTM B164 (STANDARD SPECIFICATION FOR NICKEL-COPPER ALLOY ROD,BAR, AND WIRE)

| ASTM B164 UNS N04400 | ASTM B164 UNS N04405 | ASTM B165 UNS N04400 |

ASTM B581 (STANDARD SPECIFICATION FOR NICKEL-CHROMIUM-IRON-MOLYBDENUM-COPPER ALLOY ROD)

| ASTM B581 ALLOY N06007 | ASTM B581 ALLOY N06975 | ASTM B581 ALLOY N06985 |

| ASTM B581 ALLOY N06030 | ASTM B581 ALLOY N08031 |

ASTM B 574 (STANDARD SPECIFICATION FOR LOW-CARBON-NICKEL-CHROMIUM-MOLYBDENUM, LOW-CARBON-NICKEL- MOLYBDENUM-CHROMIUM-TANTALUM, LOW-CARBON-NICKEL-CHROMIUM-MOLYBDENUM-COPPER AND LOW-CARBON-NICKEL-CHROMIUM-MOLYBDENUM-TUNGSTEN ALLOY ROD)

| ASTM B 574 ALLOY N06035 | ASTM B 574 ALLOY N10276 | ASTM B 574 ALLOY N06022 |

| ASTM B 574 ALLOY N06455 | ASTM B 574 ALLOY N06059 | ASTM B 574 ALLOY N06058 |

| ASTM B 574 ALLOY N06200 | ASTM B 574 ALLOY N06210 | ASTM B 574 ALLOY N06686 |

ASTM B 462(STANDARD SPECIFICATION FOR FORGED OR ROLLED UNS N06030, UNS N06022, UNS N06035, UNS N06200, UNS N06059, UNS N06686, UNS N08020, UNS 08024, UNS N08026, UNS N08367, UNS N10276, UNS N10665, UNS N10675, UNS N10629, UNS N08031, UNS N06045, UNS N06025, AND UNS R2033 ALLOY PIPE FLANGES, FORGED FITTINGS, AND VALVES AND PARTS FOR CORROSIVE HIGH-TEMPERATURE SERVICE)

| ASTM B 462 UNS N06030 | ASTM B 462 UNS N06022 | ASTM B 462 UNS N06035 |

| ASTM B 462 UNS N06200 | ASTM B 462 UNS N06059 | ASTM B 462 UNS N06686 |

| ASTM B 462 UNS N08020 | ASTM B 462 UNS N08024 | ASTM B 462 UNS N08026 |

| ASTM B 462 UNS N08367 | ASTM B 462 UNS N10276 | ASTM B 462 UNS N10665 |

| ASTM B 462 UNS N10675 | ASTM B 462 UNS N10629 | ASTM B 462 UNS N08031 |

| ASTM B 462 UNS N06045 | ASTM B 462 UNS N06025 | ASTM B 462 UNS R20033 |

ASTM B472 (STANDARD SPECIFICATION FOR NICKEL ALLOY BILLETS AND BARS FOR REFORGING)

| ASTM B472 UNS N06002 | ASTM B472 UNS N08020 | ASTM B472 UNS N10675 |

| ASTM B472 UNS N06030 | ASTM B472 UNS N08026 | ASTM B472 UNS N12160 |

| ASTM B472 UNS N06035 | ASTM B472 UNS N08024 | ASTM B472 UNS R20033 |

| ASTM B472 UNS N06022 | ASTM B472 UNS N08120 | ASTM B472 UNS N06059 |

| ASTM B472 UNS N06200 | ASTM B472 UNS N08926 | ASTM B472 UNS N06686 |

| ASTM B472 UNS N06230 | ASTM B472 UNS N08367 | ASTM B472 UNS N10629 |

| ASTM B472 UNS N06600 | ASTM B472 UNS N10242 | ASTM B472 UNS N08031 |

| ASTM B472 UNS N06617 | ASTM B472 UNS N10276 | ASTM B472 UNS N06045 |

| ASTM B472 UNS N06625 | ASTM B472 UNS N10665 | ASTM B472 UNS N06025 |

ASTM B166 (STANDARD SPECIFICATION FOR NICKEL-CHROMIUM-IRON ALLOYS (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, AND N06696) AND NICKEL-CHROMIUM-COBALT-MOLYBDENUM ALLOY (UNS N06617) ROD, AR AND WIRE)

| ASTM B166 UNS N06600 | ASTM B166 UNS N06601 | ASTM B166 UNS N06617 |

| ASTM B166 UNS N06690 | ASTM B166 UNS N06693 | ASTM B166 UNS N06025 |

| ASTM B166 UNS N06045 | ASTM B166 UNS N06603 | ASTM B166 UNS N06696 |

ASTM B446 (STANDARD SPECIFICATION FOR NICKEL-CHROMIUM-MOLYBDENUM-COLUMBIUM ALLOY (UNS N06625), NICKEL-CHROMIUM-MOLYBDENUM-SILICON ALLOY (UNS N06219), AND NICKEL-CHROMIUM-MOLYBDENUM-TUNGSTEN ALLOY(UNS N06650) ROD AND BAR

| ASTM B446 UNS N06625 | ASTM B446 UNS N06219 | ASTM B446 UNS N06650 |

ASTM B 649 (STANDARD SPECIFICATION FOR NI-FE-CR-MO-CU-N LOW-CARBON ALLOYS (UNS N08925, UNS N08031, UNS N08354, AND UNS N08926), AND CR-NI-FE-N LOW-CARBON ALLOY(UNS R20033) BAR AND WIRE, AND NI-CR-FE-MO-N ALLOY(UNS N08936)WIRE

| ASTM B 649 UNS N08925 | ASTM B 649 UNS N08031 | ASTM B 649 UNS N08354 |

| ASTM B 649 UNS N08926 | ASTM B 649 UNS R20033 | ASTM B 649 UNS N08936 |

ASTM B335 (STANDARD SPECIFICATION FOR NICKEL MOLYBDENUM ALLOY ROD)

| ASTM B335 ALLOY N10001 | ASTM B335 ALLOY N10665 | ASTM B335 ALLOY N10675 |

| ASTM B335 ALLOY N10629 | ASTM B335 ALLOY N10624 |

ASTM B473 (STANDARD SPECIFICATION FOR UNS N08020, UNS N08024, AND UNS N08026 NICKEL ALLOY BAR AND WIRE)

| ASTM B473 UNS N08026 | ASTM B473 UNS N08020 | ASTM B473 UNS N08024 |

ASTM B408 (STANDARD SPECIFICATION FOR NICKEL-IRON-CHROMIUM ALLOY ROD AND BAR)

| ASTM B408 UNS N08120 | ASTM B408 UNS N08800 | ASTM B408 UNS N08810 |

| ASTM B408 UNS N08811 | ASTM B408 UNS N08890 |

ASTM B511 (STANDARD SPECIFICATION FOR NICKEL-IRON-CHROMIUM-SILICON ALLOY BARS AND SHAPES)

| ASTM B511 UNS N08330 | ASTM B511 UNS N08332 |

ASTM B512 (STANDARD SPECIFICATION FOR NICKEL-CHROMIUM-SILICON ALLOY(UNS N08330) BILLETS AND BARS)

| ASTM B512 UNS N08330 |

ASTM B691 (STANDARD SPECIFICATION FOR IRON-NICKEL-CHROMIUM-MOLYBDENUM ALLOYS(UNS N08366 AND UNS N08367)ROD, BAR AND WIRE)

| ASTM B691 UNS N08366 | ASTM B691 UNS N08367 |

ASTM B425 (STANDARD SPECIFICATION FOR NI-FE-CR-MO-CU ALLOY (UNS N08825 AND UNS N08221) ROAD AND BAR)

| ASTM B425 UNS N08825 | ASTM B425 UNS N08221 |

ASTM B 573 (STANDARD SPECIFICATION FOR NICKEL-MOLYBDENUM-CHROMIUM-IRON ALLOYS(UNS N10003, N10242) ROD

| ASTM B 573 UNS N10003 | ASTM B 573 UNS N10242 |

Grades for Fittings & Flanges

| A105 | A181 | A182 | A193 | A194 | A234 | A320 | A350 | A403 |

| A181 class 60 | A182 F1 | A193 B5 | 1 | A234 WPB | A320 L7 | A350 Grade LF1 | A403 WPXM-19 | |

| A181 class 70 | A182 F2 | A193 B6 | 2 | A234 WPC | A320 L7A | A350 Grade LF2 | A403 WP304 | |

| A182 F5 | A193 B6X | 2HM | A234 WP1 | A320 L7B | A350 Grade LF3 | A403 WP304L | ||

| A182 F5a | A193 B7 | 2HM | A234 WP12 CL1 | A320 L7C | A350 Grade LF5 | A403 WP304H | ||

| A182 F9 | A193 B7M | 4 | A234 WP12 CL2 | A320 L70 | A350 GradeLF6 | A403 WP304N | ||

| A182 F10 | A193 B16 | 3 | A234 WP11 CL1 | A320 L71 | A350 Grade LF9 | A403 WP304LN | ||

| A182 F91 | A193 B8 | 6 | A234 WP11 CL2 | A320 L72 | A350 Grade LF787 | A403 WP309 | ||

| A182 F92 | A193 B8A | 6F | A234 WP11 CL3 | A320 L73 | A403 WP310S | |||

| A182 F122 | A193 B8C | 7 | A234 WP22 CL1 | A320 L43 | A403 WPS31254 | |||

| A182 F911 | A193 B8CA | 7M | A234 WP22 CL3 | A320 L7M | A403 WP316 | |||

| A182 F11 Class 1 | A193 B8M | 8 | A234 WP5 CL1 | A320 L1 | A403 WP316L | |||

| A182 F11 Class 2 | A193 B8MA | 8A | A234 WP5 CL3 | A320 B8 | A403 WP316H | |||

| A182 F11 Class 3 | A193 B8M2 | 8C | A234 WP9 CL1 | A320 B8A | A403 WP316N | |||

| A182 F12 Class 1 | A193 B8M3 | 8CA | A234 WP9 CL3 | A320 B8C | A403 WP316LN | |||

| A182 F12 Class 2 | A193 B8P | 8M | A234 WPR | A320 B8CA | A403 WP317 | |||

| A182 F21 | A193 B8PA | 8MA | A234 WP91 | A320 B8T | A403 WP317L | |||

| A182 F 3V | A193 B8N | 8T | A234 WP911 | A320 B8TA | A403 WPS31725 | |||

| A182 F3VCB | A193 B8NA | 8TA | A320 B8PA | A403 WPS31726 | ||||

| A182 F22 Class 1 | A193 B8MN | 8F | A320 B8F | A403 WPS31727 | ||||

| A182 F22 Class 3 | A193 B8MNA | 8FA | A320 B8FA | A403 WPS32053 | ||||

| A182 F22V | A193 B8MLNCuN | 8P | A320 B8M | A403 WP321 | ||||

| A182 F23 | A193 B8MLNCuNA | 8PA | A320 B8MA | A403 WP321H | ||||

| A182 F24 | A193 B8T | 8N | A320 B8A320 LN | A403 WPS33228 | ||||

| A182 FR | A193 B8TA | 8NA | A320 B8A320 LNA | A403 WPS34565 | ||||

| A182 F 36 Class 1 | A193 B8R | 8LN | A320 B8MA320 LN | A403 WP347 | ||||

| A182 F36 Class 2 | A193 B8RA | 8LNA | A320 B8MA320 LNA | A403 WP347H | ||||

| A182 F6a Class 1 | A193 B8S | 8MN | A320 B8P | A403 WP348 | ||||

| A182 F6a Class 2 | A193 B8SA | 8MNA | A403 WP348H | |||||

| A182 F6a Class 3 | A193 B8LN | 8MLN | A403 WPS38815 | |||||

| A182 F6a Class 4 | A193 B8LNA | 8MLNA | ||||||

| A182 F6b | A193 B8MLN | 8R | ||||||

| A182 F 6NM | A193 B8MLNA | 8RA | ||||||

| A182 FXm-27 Cb | 8S | |||||||

| A182 F429 | 8SA | |||||||

| A182 F430 | 8MLCuNA | |||||||

| A182 F304 | 9C | |||||||

| A182 F304H | 9CA | |||||||

| A182 F304L | 16 | |||||||

| A182 F304LN | ||||||||

| A182 F309H | ||||||||

| A182 F310 | ||||||||

| A182 F310H | ||||||||

| A182 F310MoLN | ||||||||

| A182 F316 | ||||||||

| A182 F316H | ||||||||

| A182 F316L | ||||||||

| A182 F316N | ||||||||

| A182 F316LN | ||||||||

| A182 F31Ti | ||||||||

| A182 F317 | ||||||||

| A182 F317L | ||||||||

| A182 S31727 | ||||||||

| A182 S32053 | ||||||||

| A182 F347 | ||||||||

| A182 F347H | ||||||||

| A182 F348 | ||||||||

| A182 F348H | ||||||||

| A182 F321 | ||||||||

| A182 F 321H | ||||||||

| A182 F XM-11 | ||||||||

| A182 F XM-19 | ||||||||

| A182 F 20 | ||||||||

| A182 F 44 | ||||||||

| A182 F45 | ||||||||

| A182 F46 | ||||||||

| A182 F47 | ||||||||

| A182 F48 | ||||||||

| A182 F49 | ||||||||

| A182 F56 | ||||||||

| A182 F58 | ||||||||

| A182 F62 | ||||||||

| A182 F63 | ||||||||

| A182 F64 | ||||||||

| A182 F 904 L | ||||||||

| A182 F 50 | ||||||||

| A182 F 51 | ||||||||

| A182 F 52 | ||||||||

| A182 F 53 | ||||||||

| A182 F 54 | ||||||||

| A182 F 55 | ||||||||

| A182 F57 | ||||||||

| A182 F59 | ||||||||

| A182 F60 | ||||||||

| A182 F61 | ||||||||

| A182 F65 | ||||||||

| A182 F66 | ||||||||

| A182 F67 | ||||||||

| A420 | A437 | A453 | A522 | A540 | A694 | A707 | A727 | A733 | A758 |

| A420 WPL6 | A437 Grade B4B | A453 GRADE 660 | A522 Type 1 | A540 B21 | A694 F42 | A707 L1 | A758 Grade 60 | ||

| A420 WPL9 | A437 Grade B4C | A453 GRADE 651 | A522 Type 2 | A540 B22 | A694 F46 | A707 L2 | A758 Grade 70 | ||

| A420 WPL3 | A437 Grade B4D | A453 GRADE 662 | A540 B23 | A694 F48 | A707 L3 | ||||

| A420 WPL8 | A453 GRADE 665 | A540 B24 | A694 F50 | A707 L4 | |||||

| A453 GRADE 668 | A540 B24V | A694 F52 | A707 L5 | ||||||

| A694 F56 | A707 L6 | ||||||||

| A694 F60 | A707 L7 | ||||||||

| A694 F65 | A707 L8 | ||||||||

| A694 F70 |

| A774 | A815 | A836 | A858 | A860 | A988 | B363 | B366 | B381 |

| A774 TP 304L | A815 WP27 | A836 CLASS 1 | A860 WPHY 42 | A988 S41000 | B363 WPT1 | B366 WPN | B381 F-1 | |

| A774 TP 316L | A815 WP33 | A860 WPHY 46 | A988 S41026 | B363 WPT2 | B366 WPNL | B381 F-2 | ||

| A774 TP 317L | A815 WP429 | A860 WPHY 52 | A988 S41500 | B363 WPT2H | B366 WPNCᶜ | B381 F-2H | ||

| A774 TP 321 | A815 WP430 | A860 WPHY 60 | A988 S42390 | B363 WPT3 | B366 WPHX | B381 F-3 | ||

| A774 TP 347 | A815 WP430TI | A860 WPHY 65 | A988 S30400 | B363 WPT7 | B366 WPHG | B381 F-4 | ||

| A815 WP446 | A860 WPHY 70 | A988 S30403 | B363 WPT7H | B366 WPHC22 | B381 F-5 | |||

| A815 WPS31803 | A988 S30451 | B363 WPT9 | B366 WPV602 | B381 F-6 | ||||

| A815 WPS32101 | A988 S30453 | B363 WPT11 | B366 WPHG30 | B381 F-7 | ||||

| A815 WPS32202 | A988 S31600 | B363 WPT12 | B366 WPHG35 | B381 F-7H | ||||

| A815 WPS32750 | A988 S31603 | B363 WPT13 | B366 WPV45TM | B381 F-9 | ||||

| A815 WPS32950 | A988 S31651 | B363 WPT14 | B366 WP2120 | B381 F-11 | ||||

| A815 WPS32760 | A988 S31653 | B363 WPT15 | B366 WP5923 | B381 F-12 | ||||

| A815 WPS39274 | A988 S31700 | B363 WPT16 | B366 WPHC2000 | B381 F-13 | ||||

| A815 WPS32550 | A988 S31703 | B363 WPT16H | B366 WPM21 | B381 F-14 | ||||

| A815 WPS32205 | A988 S21904 | B363 WPT17 | B366 WPH230 | B381 F-15 | ||||

| A988 S31254 | B363 WPT18 | B366 WPHC4 | B381 F-16 | |||||

| A988 S31725 | B363 WPT19 | B366 WPNCI | B381 F-17 | |||||

| A988 S31726 | B363 WPT20 | B366 WP603GT | B381 F-18 | |||||

| N08367 | B363 WPT21 | B366 WPNCMC | B381 F-19 | |||||

| A988 S32654 | B363 WPT23 | B366 WPIN686 | B381 F-20 | |||||

| A988 S17400 | B363 WPT24 | B366 WP626Si | B381 F-21 | |||||

| A988 S321803 | B363 WPT25 | B366 WPHG3 | B381 F-23 | |||||

| A988 S32205 | B363 WPT26 | B366 WP20CB | B381 F-24 | |||||

| A988 S32950 | B363 WPT26H | B366 WP3127 | B381 F-25 | |||||

| A988 S32750 | B363 WPT27 | B366 WPH120 | B381 F-26 | |||||

| A988 S39274 | B363 WPT28 | B366 WP330 | B381 F-26H | |||||

| A988 S32760 | B363 WPT33 | B366 WP6XN | B381 F-27 | |||||

| A988 S39277 | B363 WPT34 | B366 WPNIC | B381 F-28 | |||||

| A988 S32505 | B363 WPT35 | B366 WPNIC10 | B381 F-29 | |||||

| B363 WPT36 | B366 WPNIC11 | |||||||

| B363 WPT37 | B366 WPNICMC | |||||||

| B363 WPT38 | B366 WP904L | |||||||

| B366 WP1925 | ||||||||

| B366 WP1925N | ||||||||

| B366 WPHB | ||||||||

| B366 WPHN | ||||||||

| B366 WPH242 | ||||||||

| B366 WPHC276 | ||||||||

| B366 WPB10 | ||||||||

| B366 WPVB4 | ||||||||

| B366 WPHB-2 | ||||||||

| B366 WPHB-3 | ||||||||

| B366 WPH160 | ||||||||

| B366 WP3033 | ||||||||

| B366 WPH556 | ||||||||

| B462 | B564 | B637 |

| B462 UNS N08026 | B564 N02200 | B637 UNS N07252 |

| B462 UNS N08020 | B564 N02201 | B637 UNS N07001 |

| B462 UNS N08024 | B564 N04400 | B637 UNS N07500 |

| B462 UNS N08367 | B564 N06002 | B637 UNS N07750 |

| B462 UNS R20033 | B564 N06007 | B637 UNS N07718 |

| B462 UNS N06030 | B564 N06022 | B637 UNS N07080 |

| B462 UNS N06022 | B564 N06025 | B637 UNS N07752 |

| B462 UNS N06200 | B564 N06030 | B637 UNS N09925 |

| B462 UNS N10276 | B564 N06035 | B637 UNS N07725 |

| B462 UNS N10665 | B564 N06045 | |

| B462 UNS N10675 | B564 N06058 | |

| B462 UNS N06059 | B564 N06059 | |

| B462 UNS N06686 | B564 N06200 | |

| B462 UNS N08031 | B564 N06210 | |

| B462 UNS N06045 | B564 N06230 | |

| B462 UNS N06025 | B564 N06455 | |

| B462 UNS N10629 | B564 N06600 | |

| B462 UNS N06035 | B564 N06603 | |

| B564 N06625 | ||

| B564 N06686 | ||

| B564 N06219 | ||

| B564 N06985 | ||

| B564 N08020 | ||

| B564 N08031 | ||

| B564 N08120 | ||

| B564 N08330 | ||

| B564 N08367 | ||

| B564 N08800 | ||

| B564 N08810 | ||

| B564 N08811 | ||

| B564 N08825 | ||

| B564 N08904 | ||

| B564 N08925 | ||

| B564 N08926 | ||

| B564 N10001 | ||

| B564 N10003 | ||

| B564 N10242 | ||

| B564 N10276 | ||

| B564 N10624 | ||

| B564 N10629 | ||

| B564 N10665 | ||

| B564 N10675 | ||

| B564 N12160 | ||

| R20033 | ||

| R30556 |

| 50Ch14MF | 50Ch18AM-IP | 50Ch18AM-ShP |

| 50Ch20N35S2B | 50Ch25N35K15V5S | 50Ch25N35S2B |

| 50Ch25N35V5K15S | 50Ch2NMF1Ju1TR | 50Ch2NMF1JuTR |

| 50ChA | 50ChF | 50ChFA |

| 50ChG | 50ChGA | 50ChGFA |

| 50ChGL | 50ChL | 50ChN |

| 50ChN-Sh | 50ChNA | 50Cr |

| 50Cr4 | 50Cr4V1 | 50Cr4V2 |

| 50CrMo4 | 50CrMoV13-15 | 50CrNi |

| 50CrV4 | 50CrVA | 50G |

| 50G-Sh | 50G2 | 50G2-Sh |

| 50G2A | 50GA | 50GH |

| 50H | 50H21G9N4 | 50H400 |

| 50HF | 50HG | 50HS |

| 50K | 50L | 50L46 H |

| 50MgNiA | 50MgNiB | 50Mn |

| 50Mn2 | 50N | 50N-VI |

| 50N2M-1 | 50N2M-2 | 50N3ChJu |

| 50NChS | 50NP | 50PN1000 |

| 50PN1300 | 50PN250 | 50PN270 |

| 50PN290 | 50PN310 | 50PN350 |

| 50PN400 | 50PN470 | 50PN600 |

| 50PN700 | 50PN800 | 50Q |

| 50R | 50RA | 50rs |

| 50S | 50S2 | 50Si7 |

| 50SiCrMo6 | 50U0,5 (2) | 50U0,6 (2) |

| 50W1000 | 50W1300 | 50W230 |

| 50W250 | 50W270 | 50W290 |

| 50W310 | 50W330 | 50W350 |

| 50W400 | 50W470 | 50W530 |

| 50W540 | 50W600 | 50W700 |

| 50W800 | 50WCrV8 | 51 B 40 |

| 51 CDV 4 | 51 CrMnV 4 | 51 CrMnV 4 KU |

| 51 CrMoV 4 | 51 CrMoV 4 BOHLER F 500 | 51 CrV 4 |

| 51 CV 4 | 51 Mn 7 | 51 MnV 7 |

| 51 S 7 | 51 Si 17 | 51 Si 17A |

| 51 Si 7 | 51 VCr 11A | 51 VMnCr 11 |

| 51 VMnCr 11 S | 51 VMnCr 11 X | 51 VMnCr 11 XS |

| 51 VMnCr 11AT | 510 | 5105 |

| 510L | 511 | 5110 |

| 5110 G | 5112 | 5112 K |

| 5115 | 5115 G | 5117 |

| 5120 | 5120 H | 5121 |

| 5121 G | 5122 | 5122 G |

| 5130 | 5130 H | 5130 RH |

| 5132 | 5132 H | 5135 |

| 5135 H | 5140 | 5140 H |

| 5140 RH | 51403 | 51414 |

| 51416 | 51416 Se | 51420 |

| 51420 F | 51420 FSe | 51429 |

| 51430 F | 51430 FSe | 51431 |

| 51439 LL | 51440 A | 51440 B |

| 51440 C | 51440 F | 51440 FSe |

| 51442 | 51446 | 5145 |

| 5145 H | 5147 | 5147 H |

| 5150 | 5150 H | 51501 |

| 51502 | 5152 | 5155 |

| 5155 H | 5160 | 5160 H |

| 5160 RH | 5160H | 5195 |

| 51B20 | 51B30 | 51B40 |

| 51B60 | 51B60 H | 51ChFA |

| 51CrMoV | 51CrMoV4 | 51CrMoV4-17701 |

| 51CrV4 | 51L20 H | 51L30 H |

| 51L32 H | 51L35 H | 51L40 H |

| 51L45 H | 51L47 H | 51L50 H |

| 51L55 H | 51L60 H | 52 |

| 52 C | 52 CrMoV 4 | 52 D |

| 52 E | 52 Mn 5 | 52 MnCrB 3 |

| 52 N | 52 SCN 5 | 52 SiCrNi 5 |

| 520 B | 520 S | 5210 |

| 52100 | 5221 | 5221 D |

| 5223 | 5223 D | 5223 E |

| 5225 | 5225 D | 523 H 15 |

| 523 M 15 | 523H15 | 523M15 |

| 5246 | 525 A 58 | 525 A 60 |

| 525 A 61 | 525 H 60 | 527 A 17 |

| 527 A 60 | 527 H 17 | 527 H 60 |

| 527 M 17 | 527 M 60 | 5270 |

| 52C | 52CB | 52Ch2GSMF1JuT |

| 52Ch2NMF1Ju1TR | 52Ch2NMF1JuTR | 52Cr4Mo2V |

| 52CrMoV4 | 52K10F | 52K11F |

| 52K12F | 52K13F | 52K5F |

| 52K7F | 52K9F | 52K9F-SG |

| 52KF11 | 52KF5 | 52KF7 |

| 52KF9 | 52KFA | 52KFB |

| 52KFTM | 52KFV | 52N |

| 52N-VI | 52NKChBMJu | 52NTJu |

| 52SiCrNi5 | 53 | 53 MnSi 4 |

| 53 NNiMnCr 210 | 530 H 32 | 530 M 36 |

| 530 M 40 | 530-50-A5 | 530-65-A5 |

| 5310 | 5328 | 5328 D |

| 5329 | 5329 E | 5330 |

| 5330 D | 5331 | 5331 F |

| 5333 C | 5333 D | 5334 D |

| 5334 F | 5335 D | 5335 E |

| 5336 D | 5336 E | 5337 A |

| 5337 B | 5338 C | 5338 D |

| 5339 C | 5339 D | 5340 |

| 5340 D | 5341 B | 5341 C |

| 5342 | 5342 D | 5343 |

| 5343 D | 5344 | 5344 D |

| 5345 | 5346 | 5346 B |

| 5347 | 5347 A | 5348 |

| 5348 B | 5349 | 5349 B |

| 535 A 99 | 5350 | 5350 G |

| 5351 | 5351 F | 5352 C |

| 5353 B | 5354 D | 5355 |

| 5355 F | 5356 | 5356 A |

| 5357 | 5357 A | 5358 |

| 5358 C | 5359 | 5359 D |

| 5360 | 5360 D | 5360 E |

| 5361 D | 5361 E | 5362 G |

| 5362 H | 5363 D | 5363 E |

| 5364 A | 5364 B | 5365 |

| 5365 D | 5366 | 5366 D |

| 5368 | 5368 C | 5369 C |

| 5369 D | 5370 | 5370 C |

| 5371 | 5371 D | 5372 B |

| 5372 C | 5373 | 5373 C |

| 5375 | 5375 D | 5375 E |

| 5376 | 5376 E | 5376 F |

| 5377 | 5377 C | 5377 E |

| 5378 | 5378 D | 5378 E |

| 5380 | 5380 E | 5380 F |

| 5382 | 5382 G | 5382 H |

| 5383 | 5383 C | 5383 D |

| 5384 | 5384 D | 5385 |

| 5385 F | 5385 G | 5387 |

| 5387 B | 5388 | 5388 F |

| 5389 | 5389 C | 5390 |

| 5390 D | 5391 | 5391 C |

| 5391 E | 5396 | 5396 C |

| 5397 | 5397 B | 5397 C |

| 5398 | 5398 D | 5399 B |

| 5399 C | 53ChMJu | 53N |

| 54 | 54 A | 54 NiCrMoS 6 |

| 54 NiCrMoV 6 | 54 SC 6 | 54 SiCr 6 |

| 54 SiCrV 6 | 540-720 | 5400 |

| 5400 A | 5401 | 5401 A |

| 5401 B | 5402 | 5402 A |

| 5402 B | 5404 | 5404 A |

| 5405 | 5405 A | 5406 |

| 5406 A | 5407 | 5407 A |

| 5412 | 5437 | 54pp |

| 54SiCr6 | 54SiCrV6 | 55 |

| 55 C | 55 C 2 | 55 C 3 |

| 55 CNDV 4 | 55 Cr 3 | 55 Cr 3 BOHLER F 300 |

| 55 CrNiMo 4 | 55 CrNiMoV 4 | 55 CrNiMoV 4-2-4 |

| 55 CrNiMoV 5 | 55 CrNiMoVS 4 2 4 | 55 EE |

| 55 F | 55 M 5 | 55 MoCrNi 16 |

| 55 NCDV 7 | 55 NiCr 10 | 55 NiCr 12 |

| 55 NiCrMoV 6 | 55 NiCrMoV 7 | 55 NiCrMoV 7 KU |

| 55 S 7 | 55 Si 7 | 55 Si 7 RR |

| 55 SiCr 6-3 | 55 SiCr 7 | 55 SiMo 8 |

| 55 SiMoX | 55 VMoCrNi 16 | 55 VMoCrNi 17 |

| 55 W | 55 WCrV 8 KU | 55 WT |

| 550 | 550 AT | 550 A |

| 550 AT | 550 W | 550 WT |

| 5500 | 5500 D | 5501 |

| 5501 D | 5503 | 5503 D |

| 5504 | 5504 K | 5505 |

| 5505 D | 5506 | 5506 E |

| 5507 | 5507 E | 5508 |

| 5508 E | 550L | 550Y |

| 5510 | 5510 P | 5511 |

| 5511 G | 5512 | 5512 J |

| 5513 | 5513 G | 5514 |

| 5514 F | 5515 | 5515 K |

| 5516 | 5516 L | 5517 |

| 5517 J | 5518 | 5518 J |

| 5519 | 5519 L | 5520 |

| 5520 D | 5520 E | 5521 |

| 5521 G | 5523 | 5523 E |

| 5524 | 5524 J | 5525 |

| 5525 G | 5526 | 5526 H |

| 5528 | 5528 F | 5529 |

| 5529 E | 5530 | 5530 G |

| 5531 A | 5532 | 5532 E |

| 5532 F | 5536 | 5536 L |

| 5537 | 5537 F | 5537 G |

| 5540 | 5540 K | 5540 L |

| 5541 | 5541 E | 5542 |

| 5542 K | 5542 L | 5544 |

| 5544 G | 5545 C | 5545 D |

| 5546 | 5546 D | 5547 |

| 5547 F | 5548 | 5548 L |

| 5549 | 5549 F | 5550 |

| 5550 D | 5550 E | 5552 |

| 5552 D | 5552 E | 5553 |

| 5553 B | 5553 D | 5553 E |

| 5554 | 5554 C | 5555 |

| 5555 C | 5556 | 5556 G |

| 5557 | 5557 H | 5558 |

| 5558 E | 5559 | 5559 H |

| 5560 | 5560 H | 5561 |

| 5561 E | 5562 | 5562 C |

| 5563 | 5563 B | 5564 |

| 5564 B | 5565 | 5565 J |

| 5566 | 5566 K | 5567 |

| 5567 D | 5568 | 5568 E |

| 5569 | 5570 | 5570 M |

| 5571 | 5571 G | 5572 |

| 5572 G | 5573 | 5573 K |

| 5574 | 5574 D | 5575 |

| 5575 L | 5576 | 5576 H |

| 5577 | 5577 G | 5578 |

| 5578 D | 5579 | 5579 C |

| 5580 | 5580 G | 5580 H |

| 5581 | 5581 C | 5582 |

| 5582 B | 5582 D | 5583 |

| 5583 B | 5583 C | 5584 |

| 5585 | 5585 D | 5585 E |

| 5586 | 5586 D | 5586 E |

| 5587 | 5587 D | 5588 |

| 5588 E | 5589 | 5589 B |

| 5589 C | 5590 | 5590 B |

| 5590 D | 5591 | 5591 H |

| 5592 | 5592 B | 5592 D |

| 5593 | 5593 D | 5593 E |

| 5595 | 5595 E | 5596 |

| 5596 G | 5596 H | 5597 |

| 5597 C | 5597 D | 5598 |

| 5598 B | 5598 C | 5599 |

| 5599 D | 5599 E | 55A |

| 55C4 | 55C4 P25 | 55C4 P35 |

| 55C4 P50 | 55C4 P70 | 55C6 |

| 55C6 Grade 2 | 55C8 | 55C8 P25 |

| 55C8 P35 | 55C8 P50 | 55C8 P70 |

| 55C8(1) | 55C8A | 55C8M |

| 55C8R | 55Ch | 55Ch18G14S2TL |

| 55Ch20G10AMBTs | 55Ch20G10AN2MBFTs | 55Ch20G9AN4 |

| 55Ch20G9AN4B | 55Ch20G9AN4M | 55Ch6V3SMF |

| 55ChFA | 55ChGFA | 55ChGR |

| 55Cr | 55Cr3 | 55CrMnA |

| 55CrSiA | 55DTi | 55GS2 |

| We Export | ||||

| Eastern Europe | Asia | North America | Western Europe | Middle East Africa |

| Austral asia | Central South | UAE | America | Portugal |

| Spain | Indonesia | Italy | Angola | Poland |

| Brazil | Sri Lanka | Russia | Chile | Singapore |

| Oman | Venezuela | Costa Rica | USA | Qatar |

| Thailand | Canada | Saudi Arabia | Bahrain | Egypt |

| Malaysia | Turkey | Mexico | Chine | Peru |

| United States | Nigeria | Jordan | Kuwait | Dubai |

| Bangkok | Iran | Germany | UK | New Zealand |

| Vietnam | South Africa | Kazakhstan | ||